| Description/ Model | Speed | Technical | Format Range | Applications | Benefits |

|---|

VFT60

VFT200

Aerosol Valve Function Tester | 60 per minute

200 per minute | Infra-red reflective sensors to measure spray.

Option to integrate knurling station to aid anti-counterfeiting

Speed - up to 200 per minute

Available suction system which extracts sprayed active substances out of the machine. | 25 mm Diamter Cans | - Metered dose Aerosol Cans

| - Continuous Motion

- Primes valve prior to measurement

- Measures duration, no sprays, and stuck aerosol valves

|

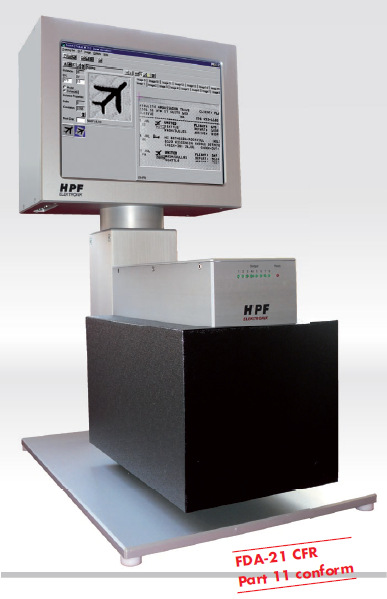

EOK-CRR

Pin hole detection | 300+ detections per minute | 10 micron hole detection

SMD LED light bank

Robust anodised aluminium housing

Precision pin hole masks for sensitivity control available as accessories in a wide range of standard and custom sizes | Any width required | - Aluminium Foil Pinhole detection

- Retrofit onto Existing Blister Machines

| - Fully Validated CFR 21 Part 11 Compliant

- Certified Pin Hole Masks to Verify System

- Self-monitoring

- Reject signal can be linked to blister machine

|

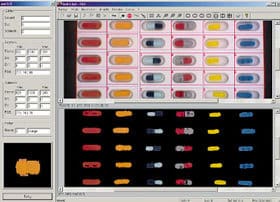

EOK FA8

Broken Tablet Detection | 600 images/min subject to viewing area. | SMD LED Lighting

Heat management by heat sink, no fans or ventilators! | As required | - Tablets or Capsules inspection in blister

- Medical Device in Blister

- Syringe in Blister

- Colour, Size or Shape of product in Blister

| - Powerful analysis of the colour classes

- Quick format changeover

- Biometric user management

- Significant evaluation statistics with detailed information

|

EOK-PQ 2

OCR and OCV Camera | 600 images/min subject to view field | Up to 12 Mega Pixels resolution

Progressive scanning colour camera with lens and add-on modules, adapted to the machine

Temperature-compensated LED reflected illumination with very long service life

Network connection (e.g. to secure data)

Touch panel or USB mouse control | As required | - OCV, OCR, 2D Matrix, Pharma Code and Barcode verification

- Blister Packs

- Bottles

- Cartons

- Lid Foil

| - Fast set-up of formats due to Simple teach-in procedure

- Can be controlled via Ethernet or from Machine PLC.

- CFR21 Compliant

- Well-arranged display

- Easy operation

- No unwanted glare

|