| Description/ Model | Speed | Technical | Format Range | Applications | Benefits |

|---|

SFS

Wrap Around Case Packers | Up to 60 Cases Per minute | De-centralised servo Drives

Up to 28 Layers per minute | | - Aerosol Cans

- Bottles

- Cartons

- Cheese and other shrink packed products

- Bakery Goods

- Chocolates

- Pots

- Flow Packs

- Stick Packs

- Tubs

| - Fast Changeover

- Flexible Format Range

- High Speed

- Cases and/or trays on the same machine

- Shelf ready and two piece designs can be produced

- Designed for 24 hour operation

|

SFS

Case Erecting Machines | < 60 cases per minute | De-centralised Servo Driven | 122 ? 407 x 87 ? 309 x 160 ? 400 mm | | - Small Footprint

- Fluted board or Cardboard

- Easy and quick changeover

|

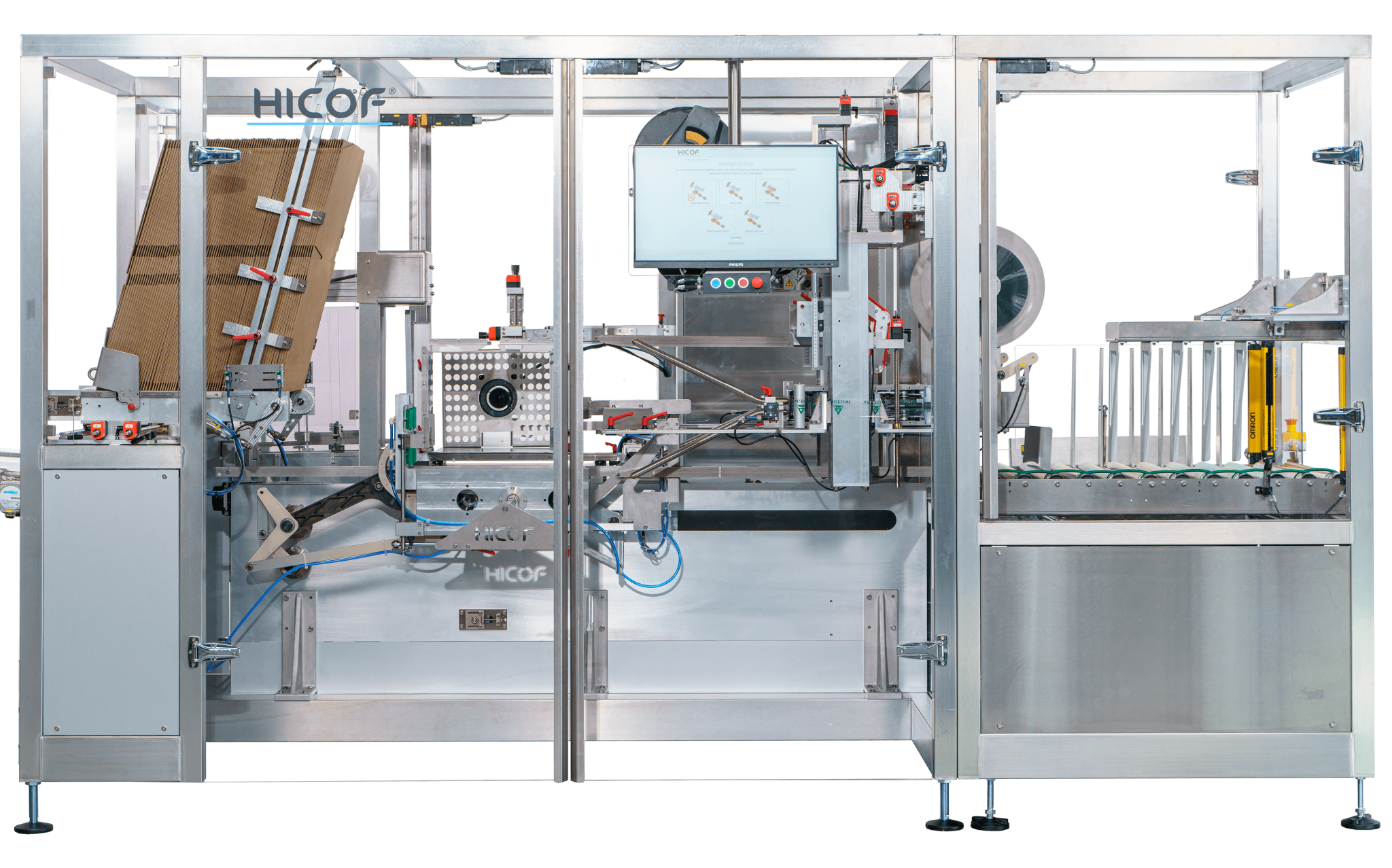

AMAPACKER 150S, 150

AMAPACKER A150, A150R

Case Packer for Pharma with Aggregation | up to 150 and 300 cartons/min

6 cases/min | Servo controlled movements

Robust compact design

Stainless steel and aluminium construction | Shipper width 250-540 mm, Depth 180-400 mm, Height 120-400 mm

| - Packing of Serialised products into Shipper Cases with Aggregation

| - Seamless integration into inhouse track and trace system or native Amacoder Track and Trace system

- Tool-less changeover

- Options include Labelling

|

SFS

Tray Packers | 60 Trays per minute

| De-centralised Servo System | | - Trays with Slots

- Special Trays designs

- Octagonal Trays

- Wrap Around Tray

- Partition loading

| - Built for 3 shift operation

- Robust welded frame

- Accurate and fast changeover

|

GO 795 Single

GO 795 Twin

GO 795 Triple

Flexible Case Erectors | 12

10

8

| Roller Doors to allow maintenance whilst running

Macralon Guards

Stainless Steel design upon request | | - Disptach

- Warehouse

- Low output per line multi-line applications

- Hand Loading

| - less than 5 minute changeover

- Up to 3 different case sizes simultaneously

- Changeover one case while others still running

|

Vario GO558 S

Vario GO558 L

Vario GO558 1

Volume Reducing case taping machine | 10 cartons/minute

6-8 cartons/minute

6 | Sensors detect incoming case footprint, height and content height

Knives slit creases to reduce height

Gummed tape dispenser seals folded flaps

Automatic volume reduction | Length 200 - 600 mm , Width 200 - 400 mm , Height 60 - 500 mm

Length 200 - 800 mm , Width 20 | - Logistics and Dispatch

- Warehouse goods out

- Consumer goods

- Internet order fulfilment

| - Reduced fill good costs

- Reduced transport costs

- Recyclable paper tape application possible

- Tamper evident gummed taped possible

- Knife free box opening with tear strip

- Additional taping positions optional

|

LP150

LP300

FP150

FP300

Gantry Robots | Up to 2 m/sec | All XYZ movements of the Gantry Robot are controlled by servo drives. Therefore our Gantry system is accurate to a couple of millimetres

Steel reinforced toothed belts drive the axes. These are precise, quiet in operation, long lasting and easy to maintain.

Up to 4 Gantry Robots can share the same working area. This makes our Gantry system ideal for applications such as palletising and order picking as multiple robots have Different solutions available to minimise the head height required by the Gantry system. The standard Gantry Robot has a fixed axis that is at least as long as the height of the pallet. An optional telescopic axis can half the Z axis and the Z-NIX axis can reduce the height above the pallet to little more than that required by the Gripper.

Our software is open source, -no black box- based on Beckhoff Soft PLC and programmed in Codesys.

Gripping can be by Vacuum, Magnet or Mechanical Clamping in rows, stacks or as individual packs. | | - Palletising across Multiple Lines

- De-Palletising

- Storing totes

- Buffering Cases or Totes

- Central palletisers

| - Compact layout

- Size and throughput expandable in the future

- Direct fast, point to point movements

- Evenly distributed floor loading

- Single gantry robot can handle multiple lines to palletise move or store

|

FP 150, LP150, FP 300, LP 300

Palletisers and De Palletisers | | | Up to 10 x 40 m Working Area | - Order picking

- Tote, case, can or bottle handling

- Multiple line palletisation

| - Direct point to point movement

- Expandable system

|

Stacker

Tote Stacking, De stacking and Palletising | Up to 1800 Crates per hour

| | 300 x 200 x 100mm to 800 x 600 x 400mm | - Totes

- Crates

- Bananna Boxes

| - Optional Automatic Format Changeover

- Intergrated Conveyors

- Stacking or De-Stacking

|

FP300, FP150

Automated Warehouse using Gantry Robots | Up to 250 picks/hr | | Wide Areas, Up to 12 x 40 m | - Warehouse

- Bakery

- Cold Store

| - Up to 4 Robots sharing the working Area

- High storage density.

- Comparatively low maintenance when compared to mini load systems.

|

FP150, FP300

Order Picking Robots | Subject to Configuration | | Areas up to 10 x 40 metres | | - Multi-product gripper

- Modular System

- Automatic layer scheme generation using Ro-Mix software

- High through puts (200 pallets per hour)

- Different pallet sizes

- Integrated wrapping possible

|

Genix-XP

Warehouse Material Handling and Buffer Systems | 2m/s subject to payload | Extra Wide - up to 20 m x 40 m

Payloads up to 1000 Kg

Point to point motion | | - Crate Storage

- Tray Storage

- Empty Crate Buffers

- Tray washer buffers

- Cold Stores management

| - Fast throughput

- Not restricted to area

- Easily expandable

|