| Description/ Model | Speed | Technical | Format Range | Applications | Benefits |

|---|

AeroSAM

Lubricant Spray Actuator Placing Machine | 60 Cans Per Minute | Siemens PLC - Electro pneumatic | up to 320 mm High cans (Taller cans on Request) | - Lubricant spray actuators with spray tubes

| - Manual or automatic feeding of actuators

- Compact footprint

- Optional presence control

- Optional ATEX compliance

|

VFT60

VFT200

Aerosol Valve Function Tester | 60 per minute

200 per minute | Infra-red reflective sensors to measure spray.

Option to integrate knurling station to aid anti-counterfeiting

Speed - up to 200 per minute

Available suction system which extracts sprayed active substances out of the machine. | 25 mm Diamter Cans | - Metered dose Aerosol Cans

| - Continuous Motion

- Primes valve prior to measurement

- Measures duration, no sprays, and stuck aerosol valves

|

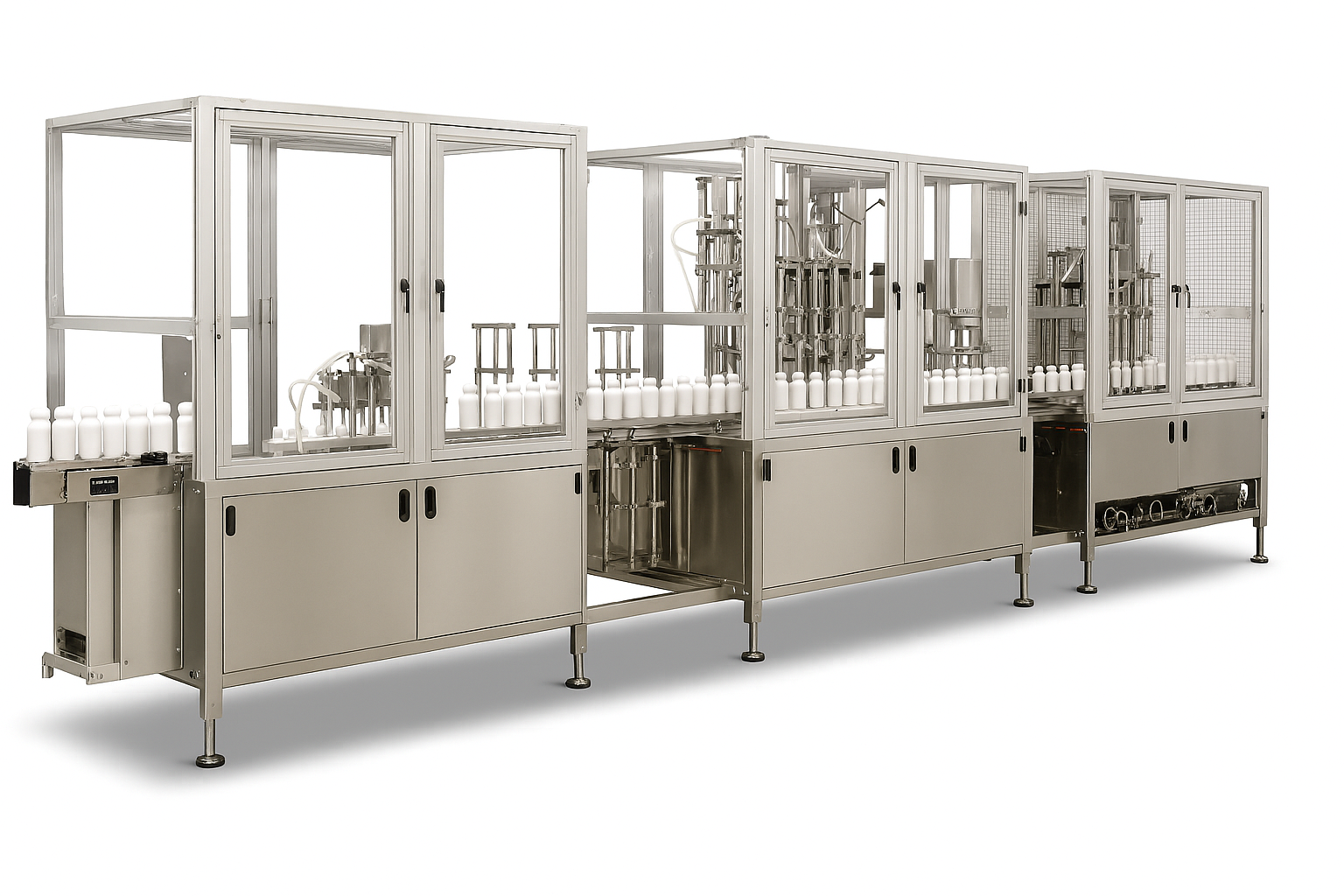

SI

DI

DLSI

DLDI

Linear Indexing Aerosol Filling machine | 40 cans/min

70 cans/m

80 cans/m

140 cans/m | Modular design

Lug chain transport

Atex rated due to air only design

No can no fill track switchers

Individual shutoff for each station

Multi stage filling

| | - Oils, Chemicals, Paints, Foods, Cosmetics, Toiletries

- Aluminium, Tin plate or glass Aerosols

| - Fast changeover with no can diameter change parts

- Quick and easy height adjustments

- Compact footprint

- Simple to maintain

- Cost effective

- Flexibility

|

AVM 738

Rotary Capping Machines | 60 bottles/min | Flexible, modular Capping Machine

Several options available including integrated labelling, induction sealing | Dia. < 90mm

Height: 40-215mm | - ROPP Caps

- CRC Caps

- Aerosol Buttons

- Press on Caps

- Corks

| - Special shaped caps and containers

- Orientation of closure to container

- Integrated labelling possible

- Press-on, Screw or Crimp

|

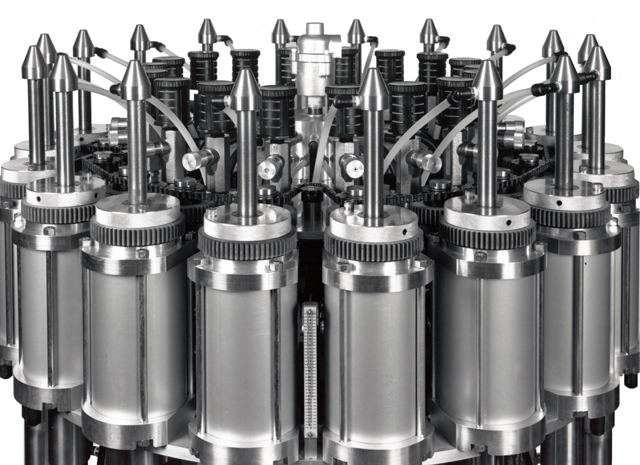

3 head

6 head

9 head

12 head

Rotary Aerosol Filling Machines | 30 to over 450 cans per minute | Made from stainless steel

Star wheel torque limiters

Variable speed drives

Single point height adjustments

Central lubrication points

Explosion proof drives

Heavy duty bearing housings | 10 cubic centimetres to 500 centimetres per station | - Terco’s rotary filling systems are ideal for high-speed aerosol production, ensuring precise liquid, valve, crimp, and propellant filling across industries like cosmetics and household products.

| - Fast toolless change part changeover

- Can be adjusted for almost any can size

|

Single Indexing

Double Indexing

Bag on valve insertion system | 25 units per minute

45 Units per minute | Under the cup gassing and crimping in the same station

Liquid filling through the valve

| All standard aerosol cans | - Most standard BOV components and valves

- Most substances

| - Can use almost any fluid e.g Gel, liquid, ointments and cream

- BOV cans are non flammable and environmentally safe

|

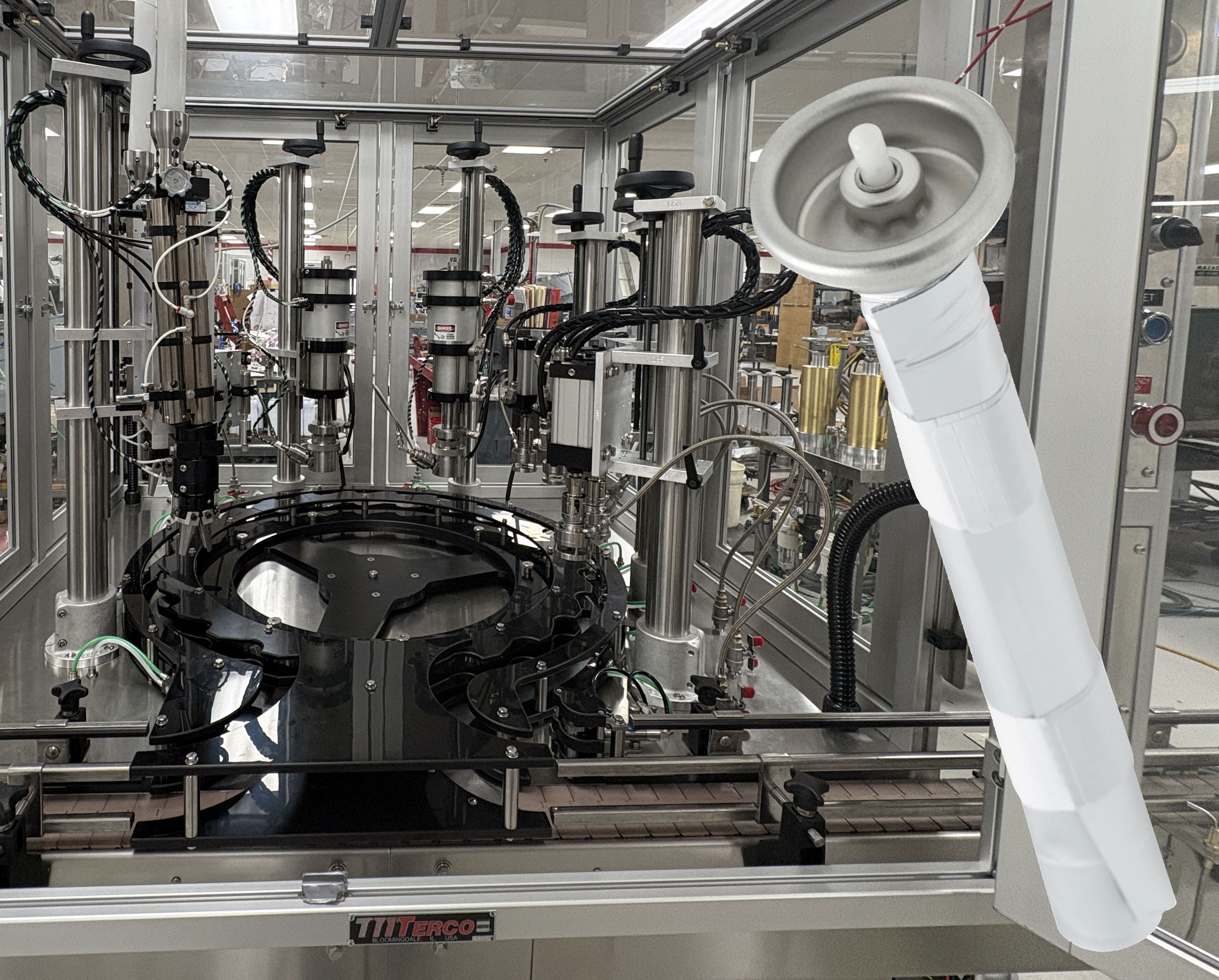

RT 070

RT 150

RT 300

Rotary buttoners | 70 cans/min

150 cans/m

300 cans/m

| Single point height adjustment

Explosion proof drive

Interlocked safety enclosures

| All standard aerosol cans | - Standard round buttons, Spray head placement, other buttons

| - toolless parts change for fast changover

- Backup queue switches for automated production

|

AVM 728

Buttoning Machine | 60 Cans Per Minute | Rake Driven Machine, rake easily exchanged to run other formats

10 Minute Changeover

Atex rated version available

Can be extended to add other functions such as fill, cap and air rinse

| Cans up to 300 mm high and 65 mm wide, Others on request | - Buttoning of Aerosol Cans

- L Shaped or protruding buttons as well as standard buttons

| - Ability to button shaped and oriented buttons or nozzles as well as normal buttons

- Fast Changeover

- Small Footprint

- Available as buttoner with capping station to place caps

- Atex rated version available

- Optional Labelling station

|

DTA 600

DTA 1200

Dip Tube Assembly Machine | 600 valves/min

1200 valves/min | Servo driven length setting allows the dip tube assemly machine to produce different length tubes at the same time

Length of dip tube can be selected on HMI touch screen

Can be fitted with multiple outfeeds on same machine

Direct feed filling machines or feed to hopper

Dip tube Laying Possible | | - Aerosol Valves

- Lotion Valves

| - Up to 3 outfeeds on the same machine

- Different lengths selected from the HMI, no manual length adjustment

- Labour savings

- Transport Savings

- Feeder savings

- Remove production problems with bent dip tubes

|

FP 150, LP150, FP 300, LP 300

Palletisers and De Palletisers | | | Up to 10 x 40 m Working Area | - Order picking

- Tote, case, can or bottle handling

- Multiple line palletisation

| - Direct point to point movement

- Expandable system

|

SFS

Wrap Around Case Packers | Up to 60 Cases Per minute | De-centralised servo Drives

Up to 28 Layers per minute | | - Aerosol Cans

- Bottles

- Cartons

- Cheese and other shrink packed products

- Bakery Goods

- Chocolates

- Pots

- Flow Packs

- Stick Packs

- Tubs

| - Fast Changeover

- Flexible Format Range

- High Speed

- Cases and/or trays on the same machine

- Shelf ready and two piece designs can be produced

- Designed for 24 hour operation

|