| Description/ Model | Speed | Technical | Format Range | Applications | Benefits |

|---|

FS1200

FS1500

FS1800

Bottle Unscrambler | 100bpm

150bpm

220bpm | | Bottle Diameter < 80mm, Bottle Height < 200mm | | - Nearly all parts are stainless steel

- Optional integrated air-rinsing unit

- Quick tool-less changeover (less than 10 mins)

- Miss-oriented bottle recognition and blow out

|

DOS 100

Topserter, Outserter machine | 120 Bottles/min | Advanced take-over-movement for exact positioning of topsert

Precise positioning of topsert on cap of bottle

Presence control of topsert on cap

Servo motor controlled motor drive of machine

Centralized height adjustment of all working stations

Nordson ProBlue4 glue-melting system

Fully automatic leaflet sorting and feeding devices | Leaflets Folded max 45 x 45 mm

Bottle Dia < 90 mm, Height < 180 mm | - Application of Leaflets to Side or Top of Bottles

| - Hot melt glueing of Leaflets

- Cycloid Pick-up motion

- Magazine or bowl fed leaflets

- Changeover to other bottle size in less than 15 minutes

|

TVM

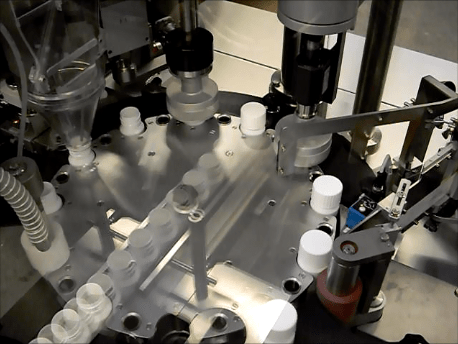

Monoblock Capsule and Tablet Counter | 60/min | Single Turret

6 Track Cremer Counter

Servo Controlled Vibratory Tracks, setting stored in Recipe

No cams to adjust under machine frame

All settings and timings adjusted from the HMI | Dia. < 90mm

Height: 40 - 215mm | - Plastic or glass bottles

- Tablet or capsule filling

- Labelling for round bottles

| - Small Footprint

- Count, Cap, label on same machine

- Labelling for round containers

- Optional in line weighing

- Quick changeover

|

TVR

Linear Monoblock Counting Machine | 100 Bottles/min and 200 counts | Servo Driven for ultimate control and fast changeover

Rake transport to reduce bottle change parts

Cremer Counting Modules

Fast changeover bottle clamps and capping heads. | Bottle Ø < 90 mm and Height < 180 mm, others on request | | - Fast Changeover from HMI

- Compact Footprint

- Can be configured to add most functions

|

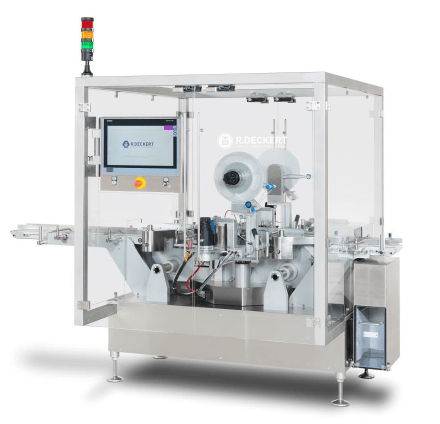

Amacoder

Serialisation Tamper Evident Labeller | 50, 100 or 150 cartons per minute

| Inkjet Printer

Pharma Code Verification

Optional Amacena Fully GxP Compliant master Data Management | Width 20 - 200 mm

Length 55 - 300 mm

Height 20 -150 mm | - Serialisation

- Labelling

- Coding

| - Fast tool-less changeover

- No change parts

- Integrated Serialisation Data

- Length only 1m

- Order Management possible from the HMI or inter/intranet

- Data Communication with Partners or Authorities

- Reporting Tools

|

DTT

Tamper Evident Track and Trace Labeller | Up to 300 Cartons per minute | | A=20-100 mm B=15-85 mm H=50-200 mm | - Serialisation of Blister Cartons

| - Fully Automatic changeover from the HMI or using a scanner

- Motor driven adjustment points

- Open to whichever Track and Trace architecture is required

- Lugged conveyor transport

- Herma labeller

- Optional vignette labeller

|

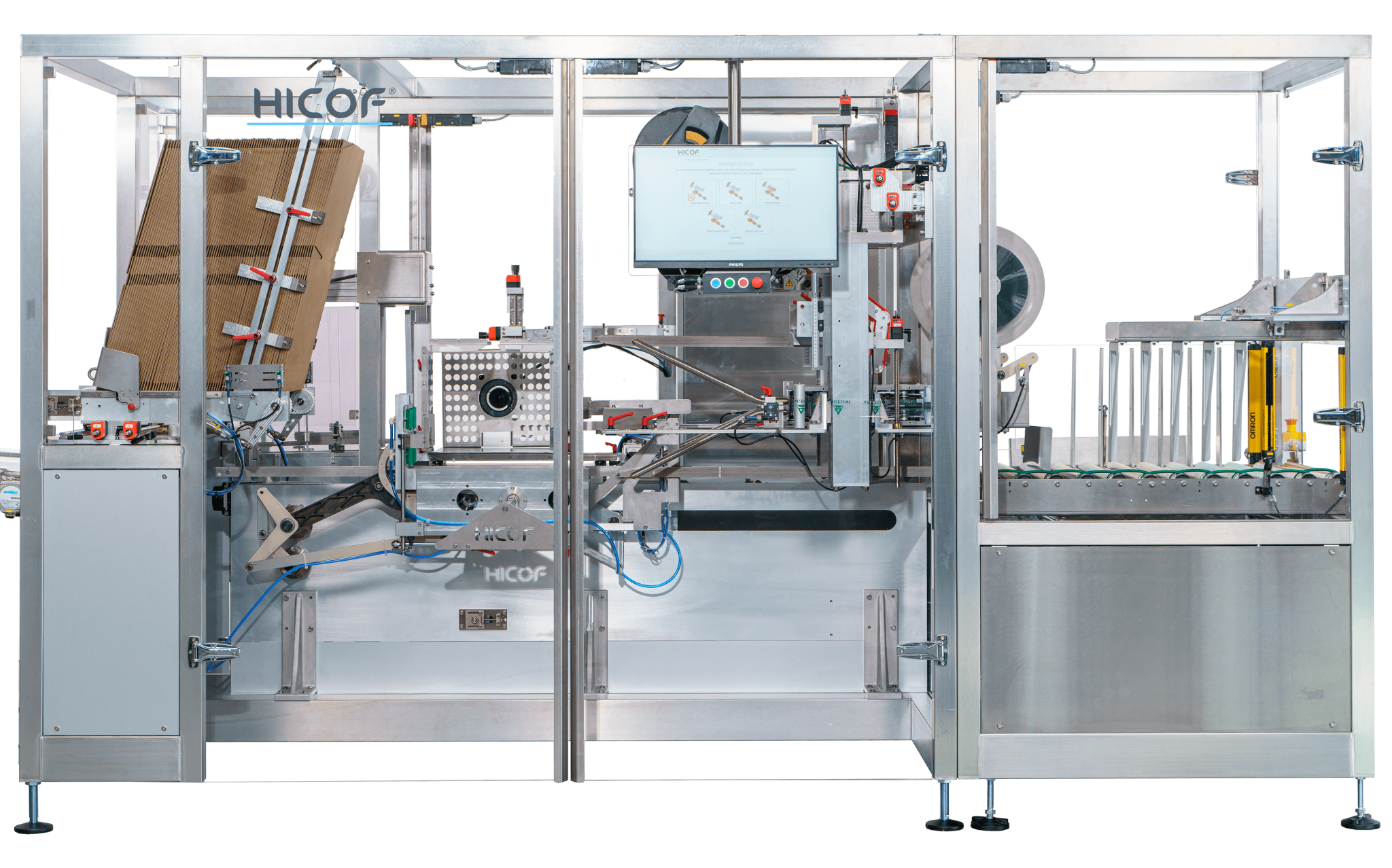

AMAPACKER 150S, 150

AMAPACKER A150, A150R

Case Packer for Pharma with Aggregation | up to 150 and 300 cartons/min

6 cases/min | Servo controlled movements

Robust compact design

Stainless steel and aluminium construction | Shipper width 250-540 mm, Depth 180-400 mm, Height 120-400 mm

| - Packing of Serialised products into Shipper Cases with Aggregation

| - Seamless integration into inhouse track and trace system or native Amacoder Track and Trace system

- Tool-less changeover

- Options include Labelling

|

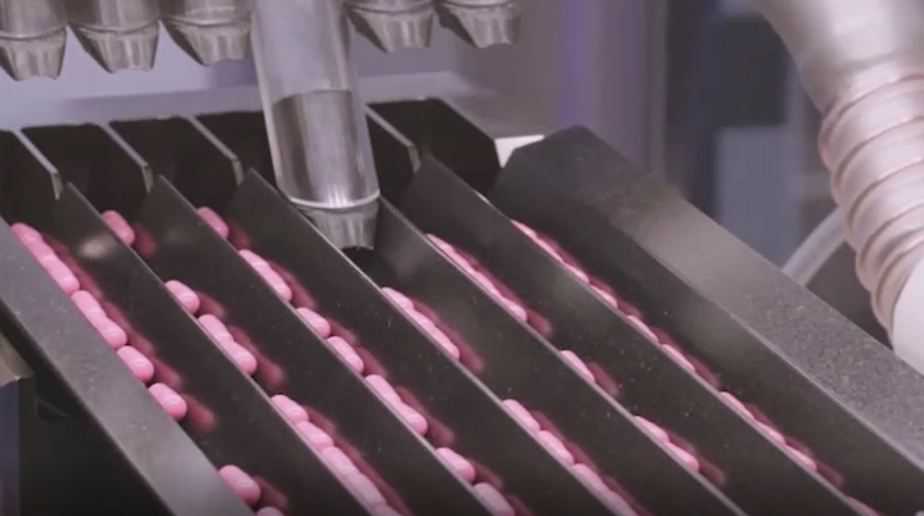

CF622

Tablet Counter | 40-400 bpm , 35 to 45 discharges/min

| Servo controlled vibration

Servo driven operation enabling easy control over HMI

Optional dipping nozzles - no escaping tablets

Automatic reject and sampling on the fly. | Tablet Length: 2 > 30 mm, Width: 2 > 20 mm,

Containers < 200 mm high, < 125 mm wide | | - 100% count accuracy

- Broken tablet inspection

- Vibratory feed

- Improved cleaning and maintenance

|

Tablet Reject

Tablet Counting Inspection System | Subject to Tablet Shape | Broken Piece detection and Reject

Rogue Table detection

Optional Automatic Tablet reject

| | - Available as option on Table counting machines

| - Automatic Detection

- No broken pieces in Bottle

|

DAB 200

ABM 400

ABM 600

ABM 800

AIL 1000

Bottle Cleaning Machines | Manual

60bpm

90bpm

120bpm

120bpm | | D <90mm, H <130mm

D <90mm, H <130mm

D <65mm, H <130mm

D <50mm, H <130mm

D <85mm, H <180mm | - Plastic containers

- Glasses

- Jars

- Pots

| - Fast changeover

- Pulsing blow and suck

- Bottles sealed to rinse unit

- Bypass possible

- Small footprint

- Cleaning process can be validated

|

CCM-AV

Automatic Vertical Cartoner | 60 cartons per minute | Optional Leaflet feeders

Optional Printers - thermal, inkjet or laser

Optional Integrated tamper-evident labels

Optional Euro-hangers | Length: 12mm - 180mm

Depth: 12mm - 120mm

Height: 45mm - 250mm | - Bottle into carton

- Blister into carton

- Canister into carton from multi-head weigher

- Bag into carton

| - Fast changeover

- Fully automatic

- Small footprint

- Quick format changeover

|

DDI 1000

Desiccant Machines | Max. 110 containers/min | Verification sensor for inserting of desiccants

Reject station for bottles which have not reached set number of desiccants

Reject verification sensor

Serial error stop of machine after 3 consecutive errors

Automatic sorting and feeding device for desiccants | Dia. < 85 mm

Height < 180 mm | - Barrel type desiccants

- Sachet type desiccants

| - Verification sensor for inserting of desiccants

- Reject station for bottles with inappropriate number of desiccants

- Reject verification sensor

- Stop of machine after 3 consecutive errors

- Sorting and feeding device for desiccants

|

DCL 100

Cottoner | Max. 100 bpm | Guillotine cut

Cotton compressor | Containers: Dia. < 85mm

Height < 180mm

Orifice dia: 16?70mm

Length of cotton: 70 ? 200 mm | | - Wisp free system

- Guillotine cut

- Cotton compressor

- Tool-less changeover

|

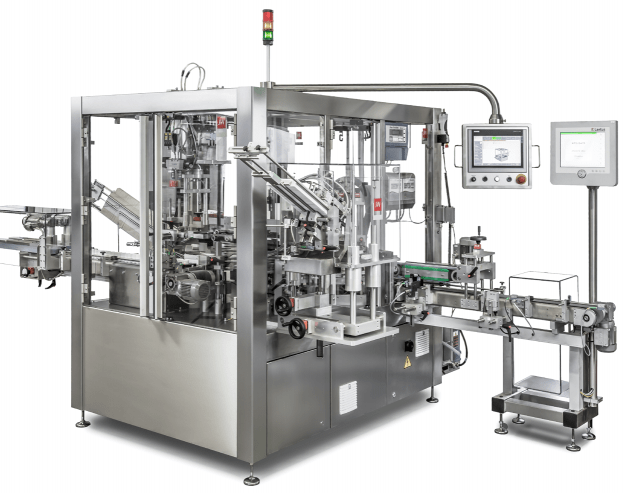

AVM 738

Rotary Capping Machines | 60 bottles/min | Flexible, modular Capping Machine

Several options available including integrated labelling, induction sealing | Dia. < 90mm

Height: 40-215mm | - ROPP Caps

- CRC Caps

- Aerosol Buttons

- Press on Caps

- Corks

| - Special shaped caps and containers

- Orientation of closure to container

- Integrated labelling possible

- Press-on, Screw or Crimp

|

AVR 200

Linear Rake Style Capping Machine | 50 cycles/min

2-3-4 up (100, 150, 200) | | Dia. < 90mm

Height < 180mm | - Nasal Sprays

- Lotion Pumps

- Buttons

- Press on Caps

- ROPP

- Corks

| - Automatic Height Changeover via HMI

- Universal rake for all bottle diameters

- No in-feed change parts

- Innovative Sorting bowls with reduced format parts

- Accessibility

- Modular Stations

|

DEM 100

Linear Labeller | Max. 200/min | | Dia. < 90mm

Height < 180mm

Max. dia. of reels: 400mm

Max. height of label-reel: 100mm | - Square bottles

- Round bottles

- Special shaped bottles

| - 3-sided labelling possible

- Small footprint

- Quick changeover

- Up to 200 bottles/min

|