| Description/ Model | Speed | Technical | Format Range | Applications | Benefits |

|---|

DAB 200

ABM 400

ABM 600

ABM 800

AIL 1000

Bottle Cleaning Machines | Manual

60bpm

90bpm

120bpm

120bpm | | D <90mm, H <130mm

D <90mm, H <130mm

D <65mm, H <130mm

D <50mm, H <130mm

D <85mm, H <180mm | - Plastic containers

- Glasses

- Jars

- Pots

| - Fast changeover

- Pulsing blow and suck

- Bottles sealed to rinse unit

- Bypass possible

- Small footprint

- Cleaning process can be validated

|

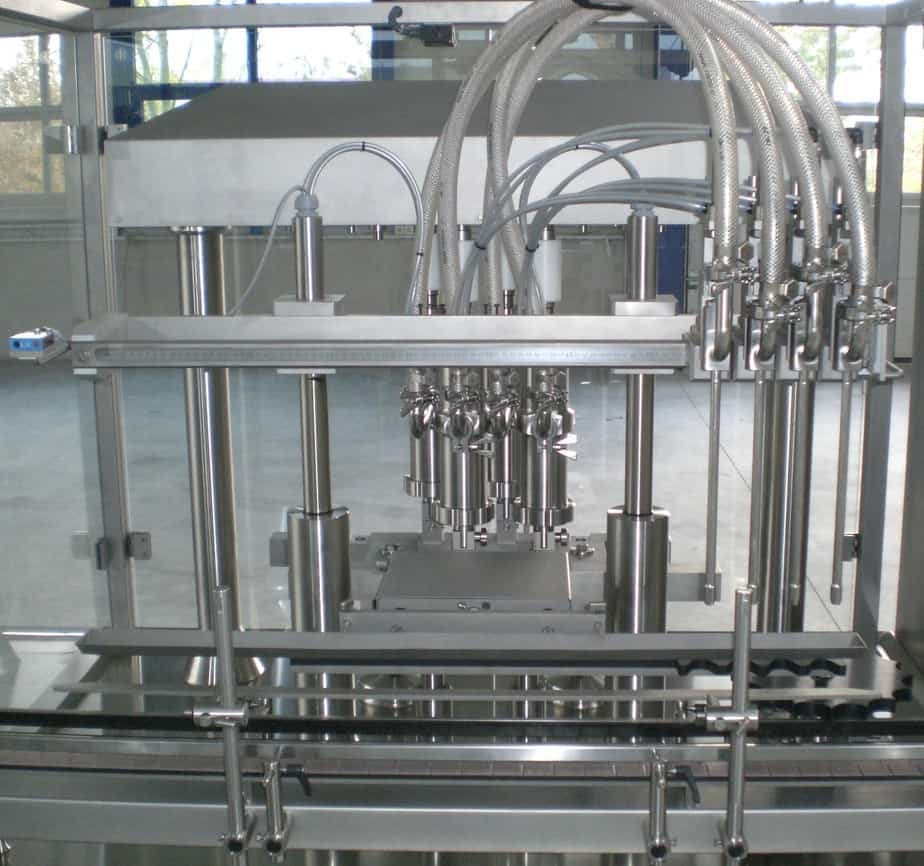

DFM

Linear Filler and Capper | 180/min with 4 heads, available with 2,4,6,8 heads | Servo driven HMI controlled formats | Dosing range: 30-310 ml

Accuracy: +/- 0,5%

Puck dia. < 60mm | | - Tool-less fast changeover

- 2,4,6,8 filling heads

- Rotary valve piston pump for thick products

- Sealless rotation piston pump for thin products

|

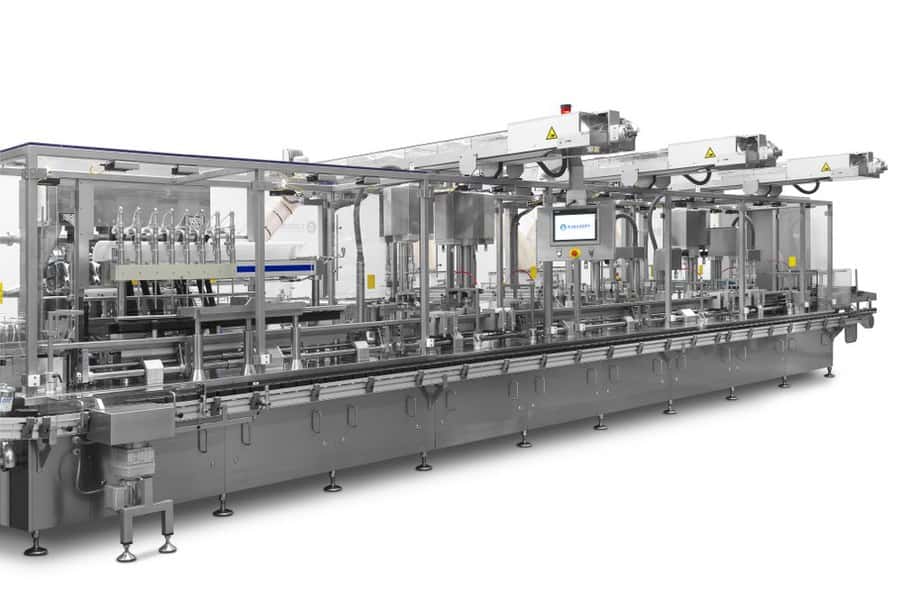

FVR

Monoblock Rake Transport Filler and Capper | Max. 200/min with 4 heads | Servo filling nozzles Dosing system tailored to liquid Modular breakdown for installation | Dia. < 90 mm, height 40 ? 180 mm | - Creams Gels Alcohol Water

| - Rotating piston pump Easily accessible Quick changeover Cams controlled from HMI and saved in Recipe High level of control and Batch reporting optional Puck transport

|

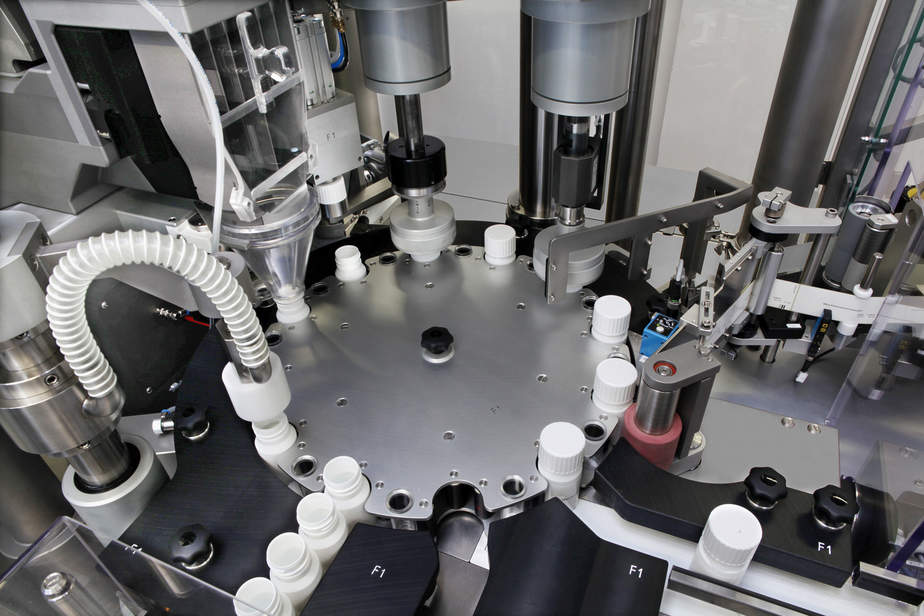

F-AVM

Monoblock Rotary Liquid Filler and Capper | 60/min | Filling with Rotating Piston pumps

or Mass Flow Filling

or Vacuum Filling

Optional Wipotec weigh cells mounted under star-wheel to verify gross and or Tare Weight.

CIP optional | Dia. < 90mm

Height: 40 ? 215mm | - Plastic or glass bottles

- Liquid, gel, cream or powder filling

| - Compact, ergonomic

- Quick changeover

- Optional labelling for round bottles

|