| Description/ Model | Speed | Technical | Format Range | Applications | Benefits |

|---|

DEM 100

Linear Labeller | Max. 200/min | | Dia. < 90mm

Height < 180mm

Max. dia. of reels: 400mm

Max. height of label-reel: 100mm | - Square bottles

- Round bottles

- Special shaped bottles

| - 3-sided labelling possible

- Small footprint

- Quick changeover

- Up to 200 bottles/min

|

DEM 738

High Speed Bottle Labeller | Max. 400 bottles/min | | Dia. < 90 mm, Height 40 < 215 mm. Others upon request | - Plastic bottles

- Glass bottles

| - High Speed

- Compact Footprint

- Herman label Applicator

- Smooth Motion

|

DTT

Tamper Evident Track and Trace Labeller | Up to 300 Cartons per minute | | A=20-100 mm B=15-85 mm H=50-200 mm | - Serialisation of Blister Cartons

| - Fully Automatic changeover from the HMI or using a scanner

- Motor driven adjustment points

- Open to whichever Track and Trace architecture is required

- Lugged conveyor transport

- Herma labeller

- Optional vignette labeller

|

Amacoder

Serialisation Tamper Evident Labeller | 50, 100 or 150 cartons per minute

| Inkjet Printer

Pharma Code Verification

Optional Amacena Fully GxP Compliant master Data Management | Width 20 - 200 mm

Length 55 - 300 mm

Height 20 -150 mm | - Serialisation

- Labelling

- Coding

| - Fast tool-less changeover

- No change parts

- Integrated Serialisation Data

- Length only 1m

- Order Management possible from the HMI or inter/intranet

- Data Communication with Partners or Authorities

- Reporting Tools

|

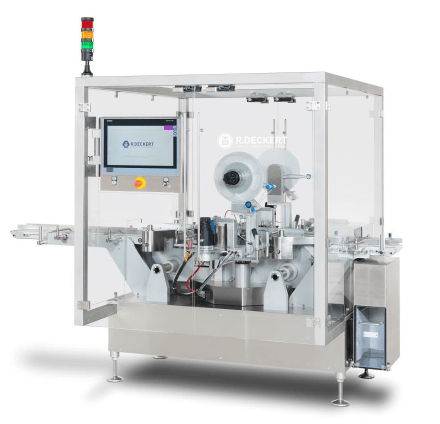

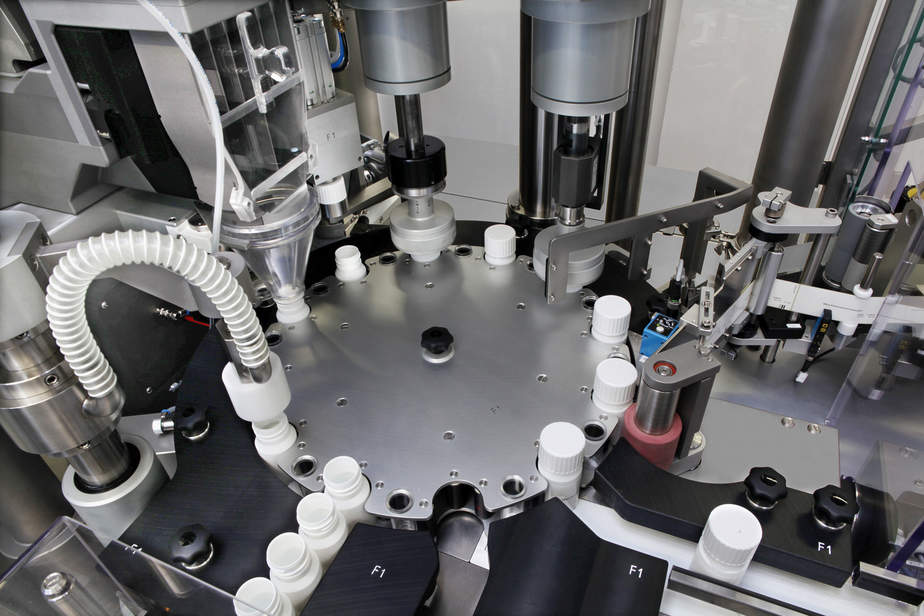

F-AVM

Monoblock Rotary Liquid Filler and Capper | 60/min | Filling with Rotating Piston pumps

or Mass Flow Filling

or Vacuum Filling

Optional Wipotec weigh cells mounted under star-wheel to verify gross and or Tare Weight.

CIP optional | Dia. < 90mm

Height: 40 ? 215mm | - Plastic or glass bottles

- Liquid, gel, cream or powder filling

| - Compact, ergonomic

- Quick changeover

- Optional labelling for round bottles

|