| Description/ Model | Speed | Technical | Format Range | Applications | Benefits |

|---|

GO 890

Semi Automatic Case Erector | Determined by Operator | | Length: 200 - 700 mm

Width: 150 - 500 mm

Height: As required | - Dispatch operations

- Manual packing operations

| - Fast changeover

- Flexible size range

|

GO750

Entry Level Case Taper for Gummed Tape | Up to 10 cases per minute | Automatically Adjusts to Case Dimensions

Top and Bottom Flap Closure

Pneumatically controlled tape dispensers

Simple PLC to recognise input | min 250 x 150 x 180 mm

max 800 x 600 x 650 mm | - Warehouse Dispatch Operations

- Manufacturing environments

- Entry Level

| - No format changeover needed

- Environmentally friendly Water Activated Gummed Tape

- Compact footprint

- Easy Reel Change

- Operator feeding

|

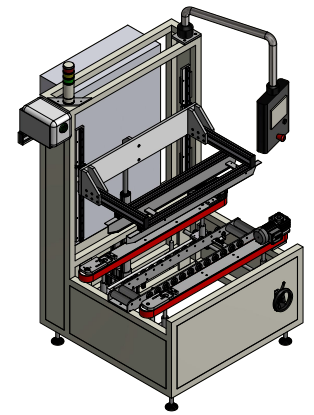

GO 795 NKB

Case Erector and Base Taper | 8-12 cases per minute | Tapes base with water activated gummed tape | Length 200 - 600 mm

Width 140 - 500 mm

Hieght 150 - 500 mm | - Shipper case erection

- Dispatch

- Production

| - Fast changeover, sustainable packaging solution for box taping

|

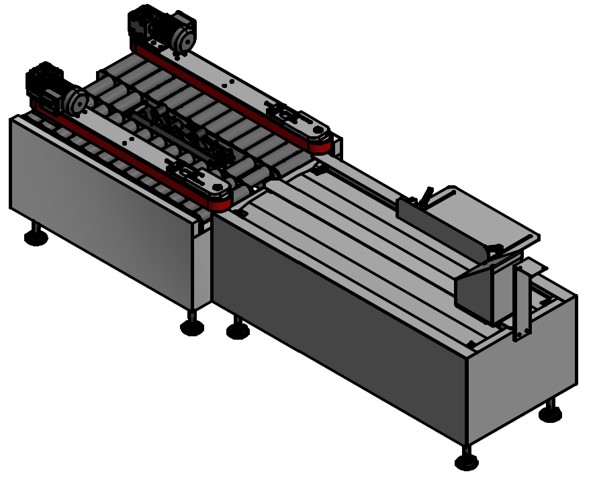

GO 795 Twin, GO 795 Quatro

Twin Case Erector and Taper | 6-8 Cases Per minute | 2, 3 or 4 Magazines

| Length 200 - 800

Width 140 - 500

Height 150 - 500 | - Dispatch operations where up to 4 different sized cases need to be produced from the same machine

| - Flexibility - Up to 4 case size at once

|

GO 651

Base Case Taper | 15 | Does not adjust automatically

Flaps closed manually by operator before cases arrive at the machine | Length 200 - 1000 mm

Width 200 - 500 mm

Height 150 - 500 mm | - Production environments

- Larger runs of the same box size

| - Manual changeover in minutes

- Fast application of environmentally friendly gummed paper tape

|

GO 653

Base Taper with Automatic size adjustment | 8 cases per minute | Automatically adjusts to case size

Bottom flaps must be closed by operator

| Length 200 - 1000 mm

Width 200 - 500 mm

Height 150 x 500 mm | - Dispatch Operations where box size varies

| - Flexible

- Wide side range

- Uses environmentally friendly water activated gummed tape

|

GO 751

Top and Bottom Taper for homogenous boxes | 15 cases per minute | Manually adjustment to case size

Manual flap closure | L 200 - ∞ mm

w 200 - 500 mm

H 150 - 500 mm

Others on request | - Production environments where there are longer runs of the same box size

| - Fast changeover in minutes

- Water activated Gummed Tape Closure

- Robust build

|

GO 753

Automatically adjusting Case Taper | 8 cases per minute | Automatic flap closure

Automatic adjustment to case dimensions | L 200 - ∞ mm

W 140 - 500 mm

H 180 - 500 mm

Others on request | - Dispatching and warehousing operations

| - Robust design

- No changeover required

- Fully automatic

|

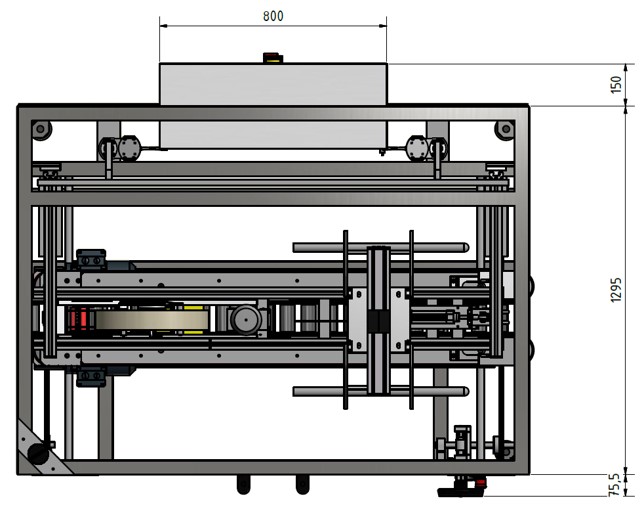

Vario GO558 S

Vario GO558 L

Vario GO558 1

Volume Reducing case taping machine | 10 cartons/minute

6-8 cartons/minute

6 | Sensors detect incoming case footprint, height and content height

Knives slit creases to reduce height

Gummed tape dispenser seals folded flaps

Automatic volume reduction | Length 200 - 600 mm , Width 200 - 400 mm , Height 60 - 500 mm

Length 200 - 800 mm , Width 20 | - Logistics and Dispatch

- Warehouse goods out

- Consumer goods

- Internet order fulfilment

| - Reduced fill good costs

- Reduced transport costs

- Recyclable paper tape application possible

- Tamper evident gummed taped possible

- Knife free box opening with tear strip

- Additional taping positions optional

|

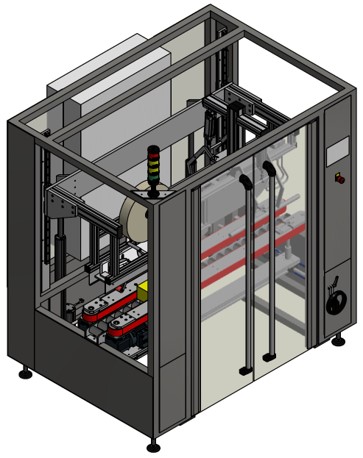

GO 757

High Output Flexible Case Taping Machine | 8 - 12 cases per minute | Auto Flap Closure

Top and Bottom Taper

Auto Adjust to Case Size | L 200 - 600 mm

W 140 - 500 mm

H 180 - 500 mm

Other dimensions on request | - Dispatch operations where every box is a different size

| - No changeover

- Eco friendly water activated tape

|