| Description/ Model | Speed | Technical | Format Range | Applications | Benefits |

|---|

SI

DI

DLSI

DLDI

Linear Indexing Aerosol Filling machine | 40 cans/min

70 cans/m

80 cans/m

140 cans/m | Modular design

Lug chain transport

Atex rated due to air only design

No can no fill track switchers

Individual shutoff for each station

Multi stage filling

| | - Oils, Chemicals, Paints, Foods, Cosmetics, Toiletries

- Aluminium, Tin plate or glass Aerosols

| - Fast changeover with no can diameter change parts

- Quick and easy height adjustments

- Compact footprint

- Simple to maintain

- Cost effective

- Flexibility

|

RT 070

RT 150

RT 300

Rotary buttoners | 70 cans/min

150 cans/m

300 cans/m

| Single point height adjustment

Explosion proof drive

Interlocked safety enclosures

| All standard aerosol cans | - Standard round buttons, Spray head placement, other buttons

| - toolless parts change for fast changover

- Backup queue switches for automated production

|

3 head

6 head

9 head

12 head

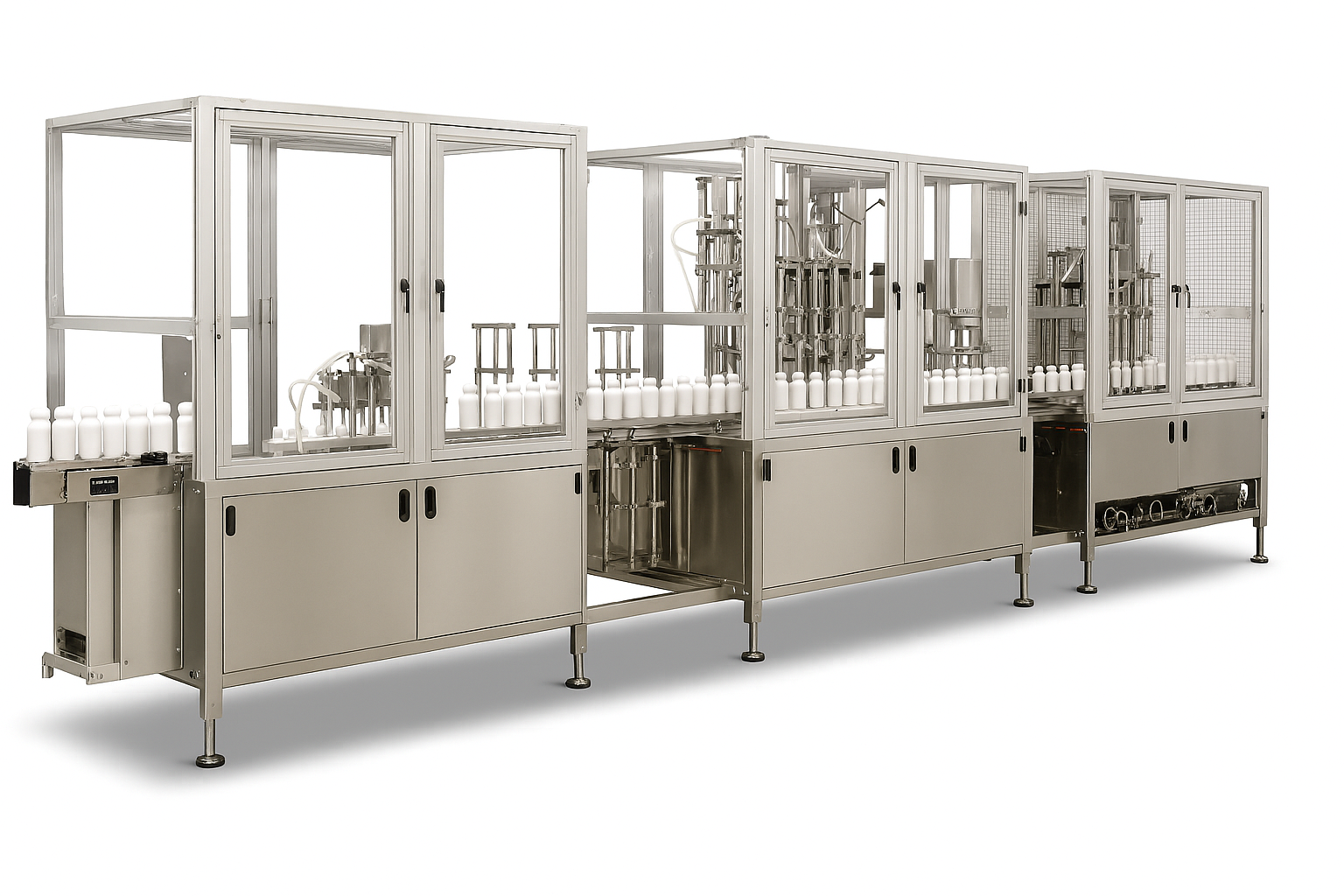

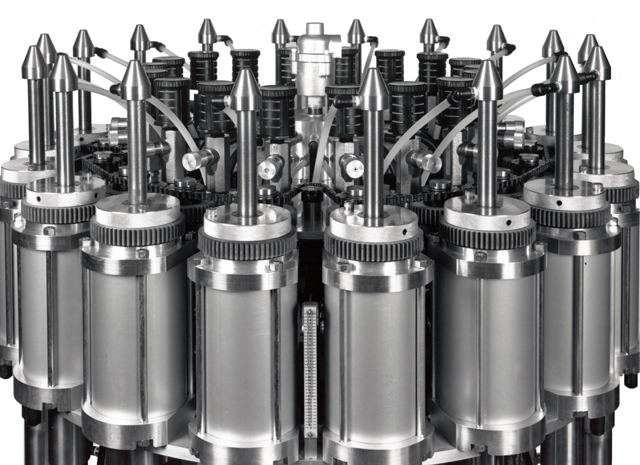

Rotary Aerosol Filling Machines | 30 to over 450 cans per minute | Made from stainless steel

Star wheel torque limiters

Variable speed drives

Single point height adjustments

Central lubrication points

Explosion proof drives

Heavy duty bearing housings | 10 cubic centimetres to 500 centimetres per station | - Terco’s rotary filling systems are ideal for high-speed aerosol production, ensuring precise liquid, valve, crimp, and propellant filling across industries like cosmetics and household products.

| - Fast toolless change part changeover

- Can be adjusted for almost any can size

|